Grasping In-Mold Decorations: Strategies, Patterns, and Best Practices for Optimum Results

In the world of production, the art of in-mold decors stands as a pivotal aspect of product design and manufacturing. In-Mold Decorations. By diving right into the approaches, trends, and best practices that underpin successful in-mold decoration processes, companies can unlock a realm of possibilities that not only raise the aesthetic appeal of their products but also improve production efficiency and reinforce consumer engagement.

Material Selection

Product selection is a critical facet of mastering in-mold decors, as it directly influences the high quality and resilience of the last product. When picking materials for in-mold designs, it is important to take into consideration elements such as compatibility with the molding procedure, the desired visual outcome, and the ecological problems the product will certainly face.

Moreover, the chosen material must possess good adhesion homes to make sure that the design sticks securely to the substratum throughout the molding process. Bond in between the material and the design is important for protecting against delamination and guaranteeing durable aesthetic appeal. Furthermore, products with high warmth resistance are chosen for in-mold designs, specifically for items that will be exposed to elevated temperature levels throughout their lifecycle. By meticulously selecting the suitable material for in-mold designs, suppliers can boost the overall quality and sturdiness of their products, satisfying the assumptions of both customers and end-users.

Style Advancement

A necessary variable in progressing the field of in-mold decorations is the continuous exploration and execution of layout advancement methods. Design innovation plays an essential role in boosting the visual charm, functionality, and total top quality of products manufactured making use of in-mold decor processes. By incorporating cutting-edge style elements, manufacturers can separate their products in the market, bring in consumers, and stay in advance of competitors.

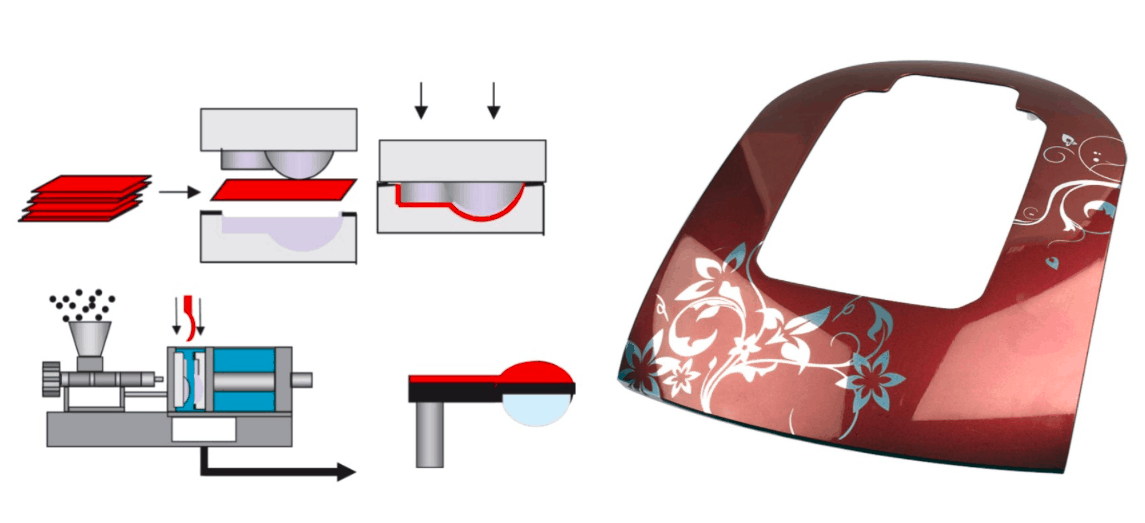

Among the crucial elements of layout innovation in in-mold decorations is the integration of intricate patterns, appearances, and graphics that were previously testing to accomplish with traditional decor techniques. Advanced technologies such as 3D printing and electronic design devices enable developers to create facility and comprehensive layouts that can be perfectly moved onto molded components. Additionally, making use of dynamic shades, metallic surfaces, and unique impacts like gloss or matte appearances can even more boost the visual charm of in-mold decorated products.

In addition, design advancement extends beyond visual appeals to include functional enhancements such as ergonomic shapes, integrated functions, and personalized elements that deal with details user requirements. By welcoming design development, suppliers can unlock new possibilities for customization, item, and creative thinking distinction in the affordable landscape of in-mold decorations.

Production Efficiency

Effective manufacturing procedures are crucial for translating the innovative designs established in the field of in-mold designs into top notch ended up items that fulfill market needs and customer assumptions. In the world of in-mold designs, manufacturing effectiveness includes different crucial elements that contribute to the general success of the manufacturing process. One essential element is the optimization of mold design and tooling to ensure precise and smooth design transfer onto the final item. By fine-tuning mold arrangements and purchasing top quality tooling products, manufacturers can enhance performance and uniformity in manufacturing.

Additionally, implementing automation and robotics in the manufacturing line can considerably boost effectiveness by streamlining recurring tasks and lowering the margin of mistake. Automation not only increases the production procedure but additionally enhances accuracy and repeatability, resulting in an extra uniform and high-quality output. Adopting lean manufacturing concepts, such as just-in-time inventory administration and waste decrease strategies, can additionally boost production effectiveness by decreasing downtime and optimizing resource use. Overall, a holistic technique to manufacturing efficiency is critical in maximizing the capacity of in-mold design strategies and attaining optimal results in the competitive market landscape.

Top Quality Control Actions

What are the key strategies for guaranteeing strict quality assurance steps in the More Help realm of in-mold decorations? Quality control measures are extremely important in in-mold decor procedures to make sure the production of flawless and top quality ended up items. One important technique is the implementation of rigorous examination procedures at every stage of the production process. This includes carrying out comprehensive visual examinations, dimensional checks, and color consistency analyses to determine any issues or variances beforehand.

Making use of advanced modern technologies such as automated assessment systems can also improve the quality control process by giving accurate and trustworthy information for analysis. These systems can find imperfections that may be missed out on by hand-operated evaluations, consequently improving overall item top quality and consistency.

Regular training and growth programs for staff members involved in the in-mold design procedure can also contribute to preserving high-quality requirements. By informing team on best practices, high quality assumptions, and the relevance of interest to information, firms can cultivate a culture of quality consciousness throughout the organization.

Customer Allure

To boost the bankability of in-mold design products, recognizing and catering to consumer choices go to my blog play a crucial role in establishing their charm and success. Offering modification choices such as personalized styles, color variants, discover this info here and textural elements can dramatically improve the appeal of in-mold decor products.

Verdict

In-mold designs provide a reliable and versatile way to boost product aesthetics. By thoroughly choosing products, welcoming ingenious layouts, maximizing production processes, implementing quality assurance procedures, and prioritizing consumer allure, producers can accomplish optimal results. It is crucial for firms to continually adapt and enhance their approaches to stay competitive out there. In-Mold Decorations. Understanding in-mold decorations requires a holistic approach that considers all facets of the manufacturing process to ensure success.

In the world of manufacturing, the art of in-mold designs stands as a critical facet of product design and production. Design innovation plays a vital function in boosting the visual appeal, functionality, and total quality of items produced utilizing in-mold decoration processes.One of the vital elements of design technology in in-mold decors is the integration of intricate patterns, textures, and graphics that were previously testing to achieve with traditional design techniques.Efficient manufacturing processes are necessary for translating the innovative layouts created in the area of in-mold decorations into top quality completed items that satisfy market demands and customer expectations. Providing customization options such as individualized designs, shade variations, and textural aspects can significantly enhance the allure of in-mold decoration products.

Comments on “Achieving Superior Finishes with In-Mold Decorations in Production”